Huntsman Polyurethanes is a global leader in MDI-based polyurethanes, serving over 3,000 customers in more than 90 countries. We have world-scale production facilities in the US, the Netherlands and China, and a global network of more than 30 downstream formulation facilities which are located close to our customers, providing highly differentiated, tailored solutions.

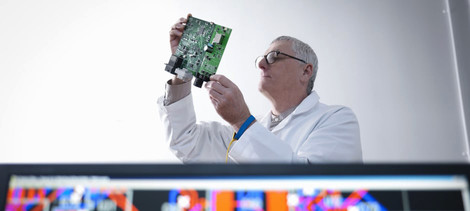

Polyurethane (PU) is one of the most versatile polymers available and can be used to create rigid and flexible foams, thermoplastic urethanes (TPUs), coatings, adhesives, sealants and elastomers. This versatility sees it being used in widespread applications across multiple industries.

Polyurethanes play a critical role in addressing many of the global megatrends affecting the world today. As the most effective thermal insulant in the market, MDI-based polyurethane is widely used to deliver energy savings solutions in residential and commercial buildings. It is used throughout the cold chain, in refrigerators and cold stores, helping preserve food.

Our lightweight composite materials improve the fuel efficiency of automobiles and forms of transportation; our coatings and TPUs provide protection and extend the life of many different products and applications; and our flexible cushioning foams provide superior comfort and enhance wellbeing. These are but a few examples of the benefits our products and solutions provide.