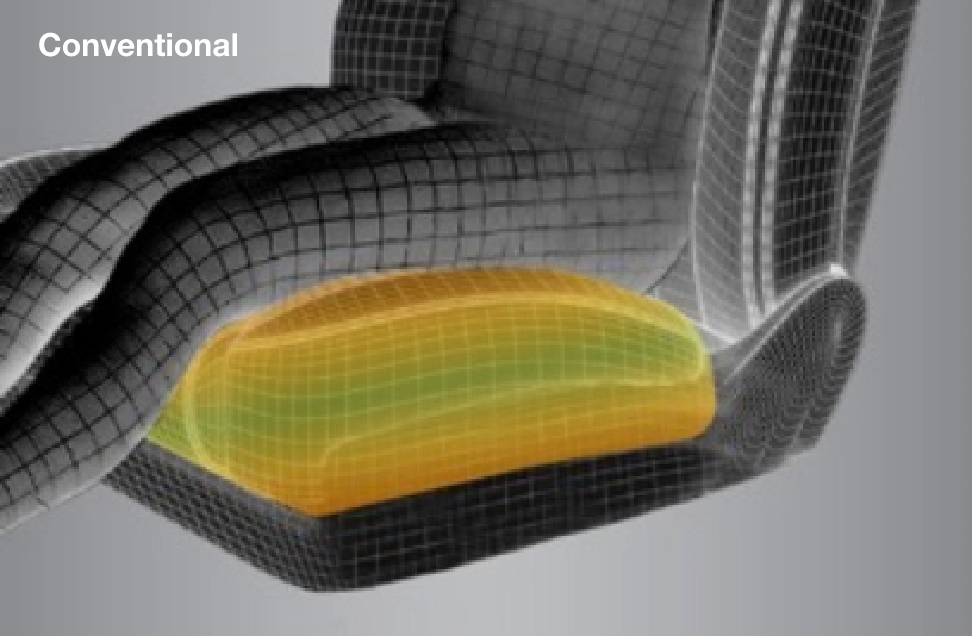

Conventional foam pads typically exhibit higher firmness closer to both the top and bottom of the mold.

- Top surface and bottom surface most firm and highest density

- Center is the softest and lowest density, not by design but as a typical occurrence

- Bottom surface usually 25% firmer than top surface

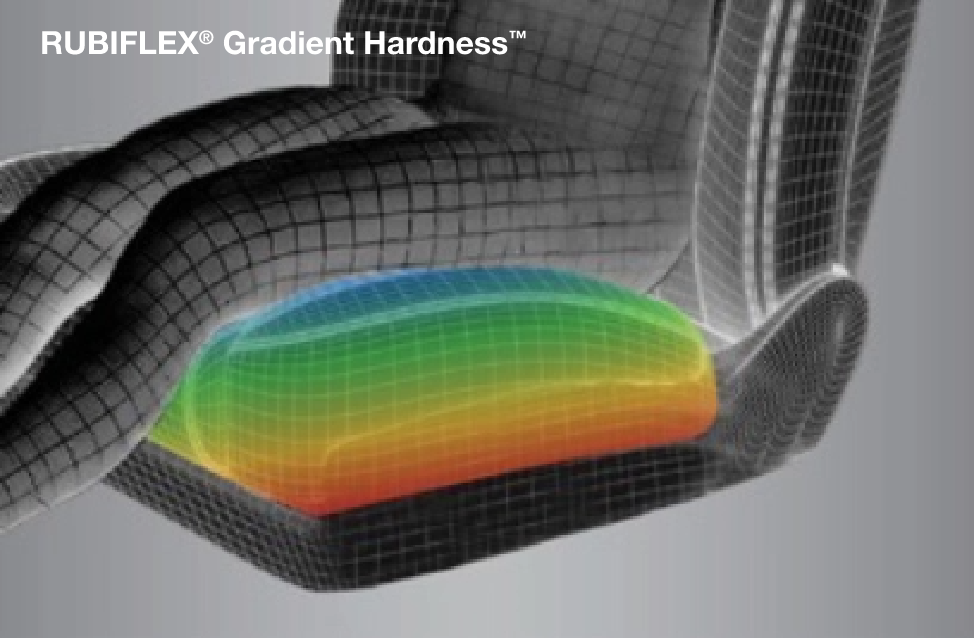

Source of the videos: These images were taken by Digital Imaging Correlation (DIC). Test results at Huntsman’s labs map the vertical strain, which can visualize the hardness gradient and measure the local stress-strain relationship.